How it Works

Inside the Solution

CON-AID - Turning Clay into a Lasting Foundation

The Blessing of Clay in Road Construction

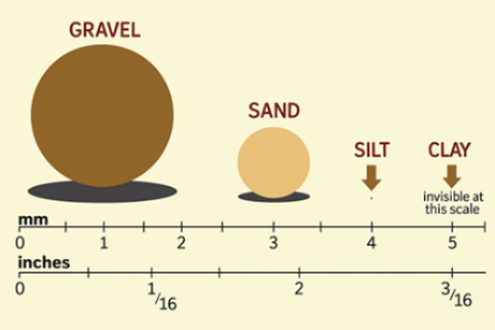

Clay is an essential component of many gravel roads. Its cohesive properties help bind soil particles together, allowing the roadbed to compact densely and support significant loads. The fine-grained structure of clay gives it a high surface area, which contributes to impressive load-bearing capacity and long-term structural integrity. In short, clay helps hold roads together—providing strength, durability, and a natural compaction advantage when properly managed.

The Curse of Clay:

Water Retention and Instability

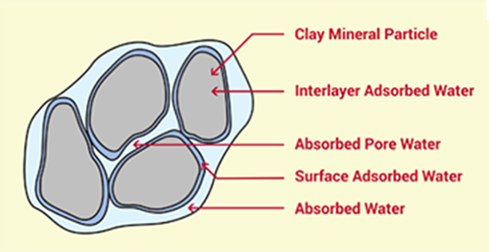

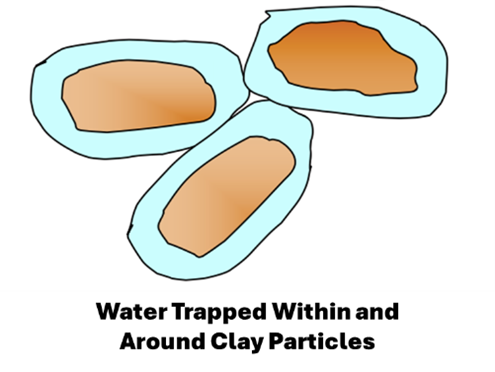

Despite its benefits, clay presents a significant problem: it attracts and holds water. This is not simple surface moisture—it’s adsorbed water, chemically bound to the clay particles due to their negative ionic charge. These electrochemical properties cause water and positively charged ions to become trapped between the microscopic layers within the clay. As a result, the soil becomes plastic, expands when wet, and contracts when dry. Roads built on untreated clay can quickly degrade, forming ruts, potholes, and structural failures—especially during freeze-thaw cycles or periods of heavy rain.

Understanding the Chemistry: Why Clay Holds Water

Clay’s water-retaining behavior is due to its layered structure and ion exchange capacity. The particles have interlayer spaces that attract and hold exchangeable cations like sodium and calcium. These ions, surrounded by water molecules, create hydrated films that cling tightly to the clay’s surface. This leads to swelling, softness, and loss of strength. Compaction becomes increasingly difficult, requiring extreme mechanical pressure to remove this water—yet even then, the clay often reabsorbs moisture after the next rain, undoing all progress.

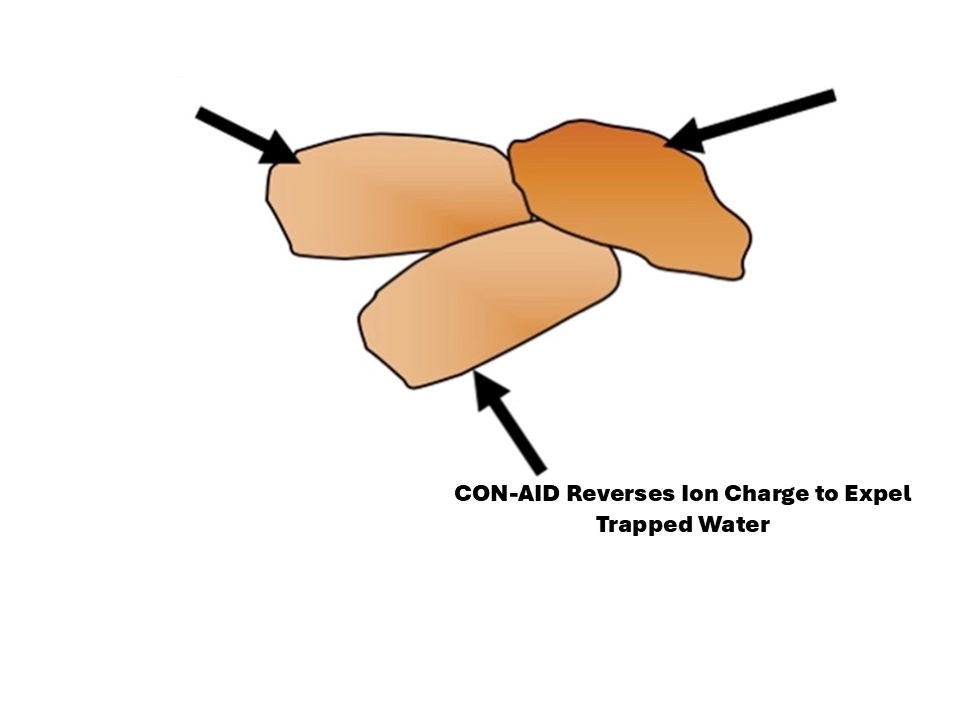

CON-AID’s Solution: Permanent Ion Exchange

CON-AID addresses this issue at the molecular level. Its formulation includes a sulphonated oil—a surfactant designed to interact with the ionic structure of clay. When CON-AID is applied, the hydrophilic “head” of the molecule chemically bonds to the charged surface of the clay, while the hydrophobic “tail” repels water. This dual-action mechanism displaces the adsorbed water and prevents it from returning, effectively neutralizing clay’s ability to trap moisture.

How CON-AID Changes Clay Behavior

Once treated, the clay particles are surrounded by a protective, oily layer that resists water. The cations that once attracted moisture are now replaced, and the hydrophobic surface prevents re-saturation. As a result, compaction can be achieved with far less mechanical effort, and the compacted material remains dense and stable—even under harsh weather conditions. Water drains more freely through the treated soil, and evaporation occurs more efficiently, further enhancing long-term stability.

Lasting Results: Stability Without Compromise

The result of using CON-AID is a roadbed that resists the destructive effects of water, maintains its structure, and reduces long-term maintenance. Unlike temporary chemical treatments, CON-AID creates a permanent transformation in the clay itself. Roads no longer suffer from swelling, soft spots, or erosion caused by trapped moisture. Instead, they benefit from clay’s natural strength—without the weaknesses that usually accompany it.

CON-AID Unlocks Clay’s True Potential

Clay doesn’t need to be removed to build a better road—it just needs to be treated right. CON-AID turns the natural ionic properties of clay from a liability into an asset. By reversing the electrochemical charge that causes clay to trap water, CON-AID stabilizes the soil permanently. The curse of clay becomes a powerful foundation for stronger, safer, longer-lasting roads.

Real Roads, Real Results

CON-AID in the FIELD

Viking, AB

Grain elevator road treated with CON-AID 26 years ago—once impassable, now supports 75 B-trains daily and remains solid and stable.

MEG Well Pad, AB

CON-AID removed trapped moisture, creating a dense, well-compacted, and stable well pad that sped up construction and reduced material costs.

Hwy 604, AB

One of Alberta’s heaviest haul roads—served three major gravel pits and held strong without re-treatment.

RM of Sherwood, SK

Global Transportation Hub road treated—went from weekly grading to twice in three months.

MEG Energy Main Road, AB

The treated section needs minimal maintenance—untreated portions are graded daily.

MEG Energy Well Pad, AB

CON-AID created a dry, stable pad—faster builds, less gravel, lower costs.

Trusted by Those Who Build

Our Clients